How do you choose the right camera for visual road inspections?

Table of Contents

A guide to selecting the right camera for visual road inspections

Roads are the lifelines of modern transportation systems, connecting cities, towns, and communities. Ensuring their safety, durability, and efficiency is crucial for both commuters and governments.

In the quest for well-maintained roads, visual road inspection stands as a guardian of this public asset. It is a systematic approach that ensures our roads meet the high standards required for today’s transportation needs. Among the tools at our disposal is the Pavement Condition Index (PCI), a precise measure that guides maintenance decisions and budget allocations.

This article will navigate through the intricate landscape of road inspection. We’ll explore the nuances of the PCI and its role within the broader context of visual inspection. We’ll share steps on how to systematically proceed with visual road inspections under various conditions, emphasizing the importance of the right hardware—specifically, the type of camera used.

Understanding what to inspect and the end-use is crucial. Whether it’s for routine maintenance or post-disaster assessments, the type of images captured and the information collected from them can make all the difference. We’ll delve into defining the necessary image types for effective inspection and the information needs that drive this process.

What is the PCI?

The Pavement Condition Index* (PCI) is a standardized numerical rating that quantifies the overall condition of road pavements. It provides valuable insights into the health of road surfaces, allowing authorities to prioritize maintenance and allocate resources effectively. The PCI score ranges from 0 (completely failed) to 100 (excellent condition).

The PCI is not just a mere number; it encapsulates a wealth of information about the pavement’s condition and plays a crucial role in the strategic planning of maintenance and rehabilitation activities. When conducting a PCI assessment, inspectors systematically evaluate various distress factors that affect the pavement’s performance. These include:

- Surface Distress: This encompasses a variety of issues such as cracking patterns (alligator, block, edge, longitudinal, and transverse), potholes, rutting, and other visible signs of wear that can compromise the pavement’s integrity and safety.

- Roughness: A key indicator of a road’s comfort and drivability, roughness is assessed by measuring the smoothness or roughness of the pavement surface. It is often quantified using the International Roughness Index (IRI), which reflects the cumulative vertical movements or vibrations over a specified distance.

- Structural Integrity: This refers to the pavement’s ability to support loads without sustaining damage. It is crucial for ensuring that the pavement can withstand the daily traffic demands without deteriorating prematurely.

By evaluating these parameters, engineers and transportation agencies gain a comprehensive understanding of the road network’s condition. This knowledge informs decisions on repairs, rehabilitation, and long-term planning.

When it comes to visual road inspection, surface distress is the primary factor we capture and analyze. It is the cornerstone of visual road inspections.

Inspecting Roads: A spectrum of requirements

One of the first questions we often hear from our clients is “What do I need for visual road inspection?”

Not every road inspection project requires the same set of variables that dictate:

- The Purpose of the Inspection: Is it for routine maintenance, pre-construction surveys, or post-disaster assessments?

- The list of objects and features, which have the focus. This can be the condition of the road surface and or the right-of-way objects such as traffic signs, light poles, guide rail, drainage and gullies

- Local regulations: The specifics of visual road inspection can vary depending on regional standards and requirements. In the Netherlands, for instance, there is an focus on tiny details such as raveling. When in India the focus shifts to more prominent issues like large potholes.

Armed with this knowledge, we can now make a more informed decision about the specific equipment required for visual road inspection.

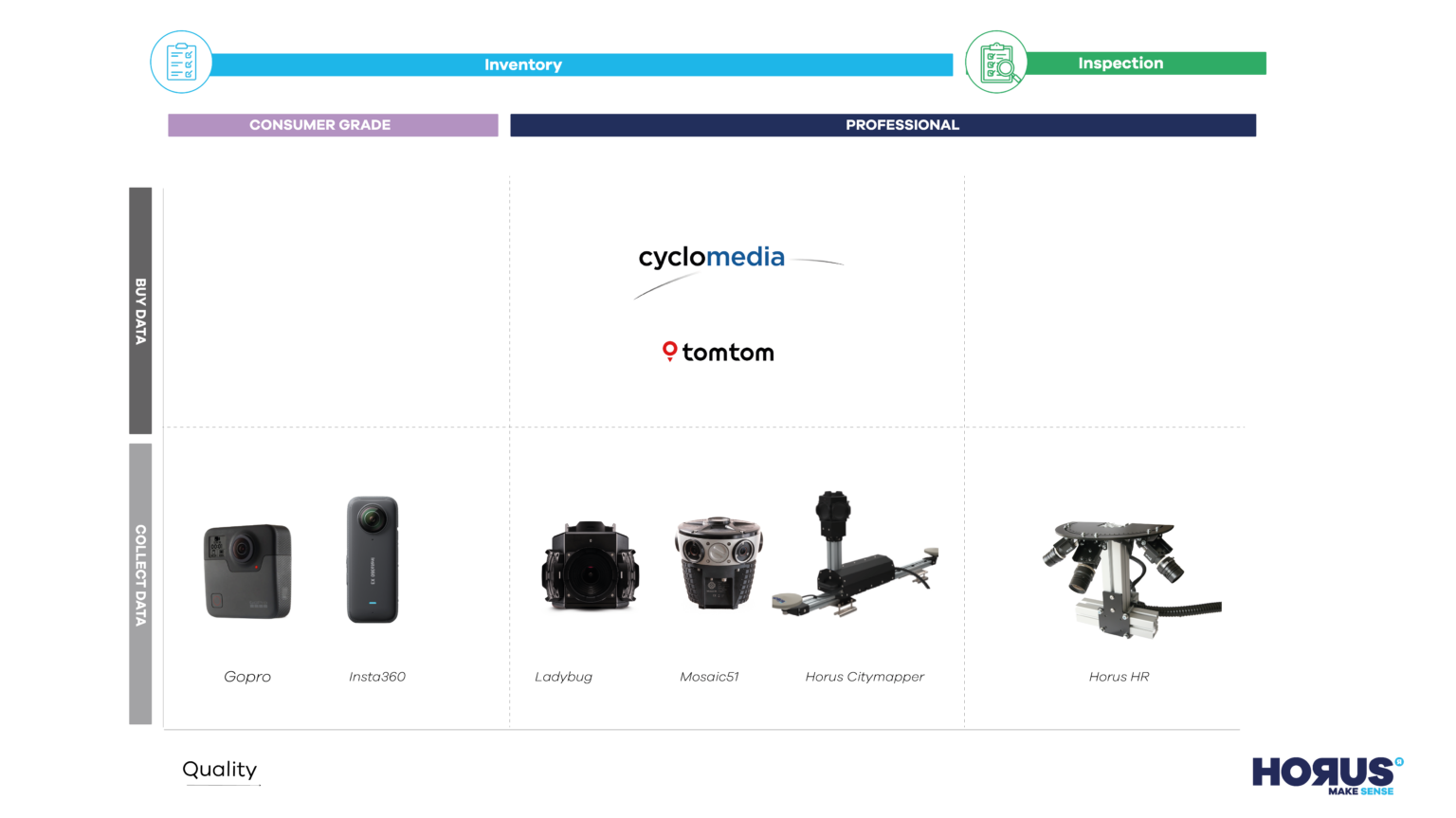

Evaluate the hardware options

Selecting the right hardware is a critical step in visual road inspection, where the equipment used can significantly impact the quality of data gathered. In this section, we evaluate various hardware options, ranging from consumer-grade cameras to specialized high-resolution imaging systems. Understanding the strengths and limitations of each option is essential to ensure that the chosen equipment aligns with the goals of the inspection, whether for a broad overview or detailed analysis.

Consumer-Grade Cameras like GoPro and Insta 360 are more affordable and portable. They are suitable for basic inspections and can capture a wide field of view, which is useful for general assessments.

In addition to the image quality, the position accuracy of the GPS/GNSS system and the synchronization with the images also affects the quality of the data and thus may or may not be suitable for a road inspection use case. Check out our video “What kind of equipment does my mobile mapping project needs” for more information about this subject.

Specialized Cameras such as Ladybug, Mosaic, and Horus High resolution (HR) cameras offer higher resolution and better image quality, which is necessary for detailed inspections. These cameras can capture finer details and are better suited for comprehensive damage assessments.

- GoPro and Insta 360 Cameras: These cameras typically produce images with a wide-angle view. They are good for capturing large areas but may lack the detail required for close-up inspections of road damage.

- Ladybug and Mosaic Cameras: These cameras provide panoramic images with high resolution, allowing for detailed inspections over larger areas.

- Horus High resolution (HR) Camera: This is a high-end camera system designed specifically for road inspections, providing extremely high-resolution images that can capture even the smallest road defects.

For accurate assessment of pavement conditions, high-resolution images are essential. Horus’s high-resolution inspection cameras provide the clarity necessary for detailed inspection and comprehensive (damage) assessments.

Setting up the inspection process

When it comes to streamlining the inspection process for visual road assessment, Horus offers powerful tools. One such tool is the Layermanager. Here’s how it fits in:

- Customized Inspection Forms: The Layermanager allows you to create personalized inspection forms tailored to your specific needs. Define the attributes you want to record for each pavement feature (e.g., cracks, potholes, raveling patches).

- Attribute Data Collection: Inspectors use the Layermanager to input attribute data during field inspections. Record information such as crack length, pothole dimensions, and surface distress severity.

- Mapping in GIS: The Layermanager seamlessly integrates with Geographic Information Systems (GIS). The extent of damage (length of crack or area of a raveling patch) is then automatically calculated and mapped in GIS.

Data collected during inspections is mapped spatially, providing a visual representation of pavement conditions. Decision-makers can identify trouble spots, prioritize repairs, and allocate resources efficiently.

Unlocking precision and efficiency

By integrating Horus’s high-resolution inspection cameras into your workflow, you:

- Minimize Subjectivity: Objective data replaces guesswork.

- Accelerate Assessments: Quickly evaluate large stretches of road.

- Make Informed Decisions: Prioritize repairs based on accurate information.

- Add security and accountability to the inspection process by working digitally

Curious about how these cameras work? Witness firsthand how Horus cameras capture every detail, from cracks to surface distress.

Conclusion

The Pavement Condition Index (PCI) is the overarching methodology for assessing a road, within which visual road inspection is an indispensable component, providing not just a snapshot but a comprehensive view of the road’s condition.

The choice of camera—be it a consumer-grade GoPro, an Insta 360, a specialized Ladybug or Mosaic, or the high-end Horus HR—can make a significant difference in the quality of data collected. Each project’s unique requirements dictate the level of detail necessary.

Ready to take the next step in ensuring your roads are in top condition? Our team of experts is here to guide you through the process. With cutting-edge camera technology and comprehensive inspection services, we’ll help you make informed decisions about road maintenance and asset management. Contact us today or to book a meeting with one of our sales experts. Together, we’ll pave the way to safer, smoother roads.